CORIOLIS MASS FLOW METER VS. THERMAL MASS

- Home

- Application Guide

- CORIOLIS MASS FLOW METER VS. THERMAL MASS

Coriolis Mass Flow Meter vs Thermal Mass Flow Meter

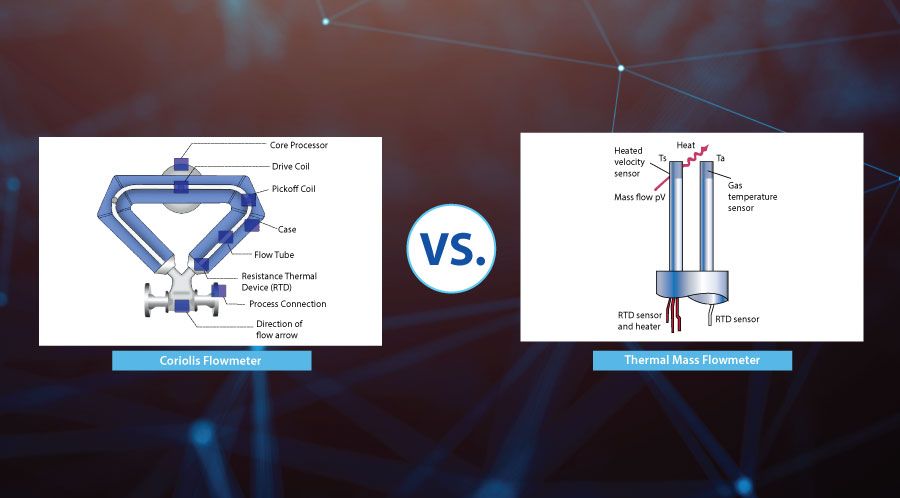

The two types of mass flow meters predominantly used to detect the mass flow rate of fluids are the Coriolis mass flow meter and the Thermal mass flow meter.

The Coriolis flow meter measures the mass flow rate of the fluid with respect to a fixed point in the tube. The quantity of fluid flowing past the fixed point in a given amount of time is the mass flow rate of the fluid. Thermal flow meters derive the mass flow rate of the fluid by calculating the cooling effect produced by the fluid in the temperature sensors.

It is important to understand that the mass flow rate is measured by these devices, not the volumetric flow rate. The volumetric flow rate differs for every fluid based on the density, pressure, temperature, and composition of the fluid and can be calculated by dividing the mass flow rate by the density of the fluid. Volumetric flow is constant for fluids with constant density, however, as density varies with pressure and temperature, the volumetric flow rate varies accordingly.

Standard mass flow meters compensate for temperature and pressure differentials through multivariable transmitters or flow software and are programmed to present output in terms of mass flow rate and volumetric flow rate at standard temperature and pressure.

Presented here are the methods of operation and applications for Thermal mass flow meters and Coriolis mass flow meters.

THERMAL MASS FLOW METER: METHOD OF OPERATION

Thermal mass flow meters are based on the principle of measurement of mass flow based on the rate of heat dissipation per unit time. The flow meter is comprised of two temperature sensors protruding into the fluid flow up to a specified depth. A constant heat flow is supplied to the fluid through the velocity sensor while the other sensor measures the temperature of the fluid. The amount of heat dissipated determines the mass flow rate of the fluid.

There are two methods of calculating the amount of heat dissipating in the fluid, described as follows:

- Constant Temperature Differential Method

In this method, a constant temperature difference is maintained between the two temperature sensors. The current supplied to keep this difference constant differs as per the flow rate of the fluid. The greater the mass flow rate, the greater is the cooling effect of the velocity sensor, and hence, greater the amount of current supplied through the RTD. The change in power is a direct measure of the flow rate of the fluid.

- Constant Current Method

In this method, a constant current is supplied to the velocity sensor, while the temperature sensor measures the temperature of the fluid. The velocity sensor records varying temperatures based on the amount of fluid flowing through the pipe. The difference between the two sensors is an indication of the mass flow rate of the fluid. The greater the mass flow rate, the smaller the temperature difference.

Both these flow meters measure the cooling effect produced on the velocity sensor by the fluid molecules. Thermal mass flow meters are primarily used to measure flow rates for gases as they have lesser heat absorption capacity as compared to liquids.

Thermal Mass Flow meters: Applications

Thermal mass flow meters find application in various fields where gas flows have to be measured. These include:

- Detection of Sulphur Dioxide (SO2) and Nitrogen Oxides (NOx) in greenhouse gas emissions

- Measurement of the air to fuel ratio in boilers and steam generators

- Monitoring of gas flares in natural gas and biogas plants

- Testing of gas valves and pressure regulators for leaks

- Measurement of compressed air flow in industrial applications

CORIOLIS MASS FLOW METER: METHOD OF OPERATION

The working principle of the Coriolis Mass Flow meter is based on Newton’s second law of motion, i.e. the mass of a fluid is inversely proportional to its acceleration. Coriolis Mass flow meters are designed with a bent or straight sensor, through which the fluid flow is mapped.

In the bent-tube design, the velocity sensor tube is made to vibrate using electromagnetic current, at a small fixed amplitude. Sensors are fixed at the inlet and outlet junctures of the tube, at equal distances from the central fixed point. When there is no fluid flowing through the tube, the amplitude is constant and the sensors at either end are in phase with one another.

When fluid starts flowing through the tube, the inertia of the fluid causes the amplitude of the measuring tube to change. This creates a phase difference between the entry and exit sensors which is measured in terms of time. The time difference measured is used to calculate the mass flow rate of the fluid.

Coriolis flow meters are applicable for mass flow measurement in liquids as well as gases, but are prominently used for liquids as a high-density fluid is required to maintain the momentum of oscillation which is critical for measuring the mass flow rate.

Coriolis Mass Flow meters: Applications

Coriolis mass flow meters are used in various applications where liquid flow rate has to measured accurately. These include:

- Industrial applications such as measurement of mass flow rate for solvents, adhesives, resins, and more

- In food and beverage industries for critical flow measurement during bottling and packaging

- In the oil and gas plants for detection of fluid flow rate

- As positive-displacement meters in downstream petroleum fluids in the petrochemical industry

- Mining, mineral processing, paint, coating, and sealant applications

CONCLUSION:

In terms of accuracy, the Coriolis mass flow meter is superior to the Thermal mass flow meter which makes it the natural choice for custody-transfer applications. However, the high cost of the Coriolis flow meter deters their use in applications where accuracy is secondary. The recent developments in Thermal mass flow meters, such as improved flow sensitivity, advanced computational algorithms to detect accurate mass flow rate, and hyper-fast microprocessors have led to increased use of Thermal mass flow meters at much less installation cost.