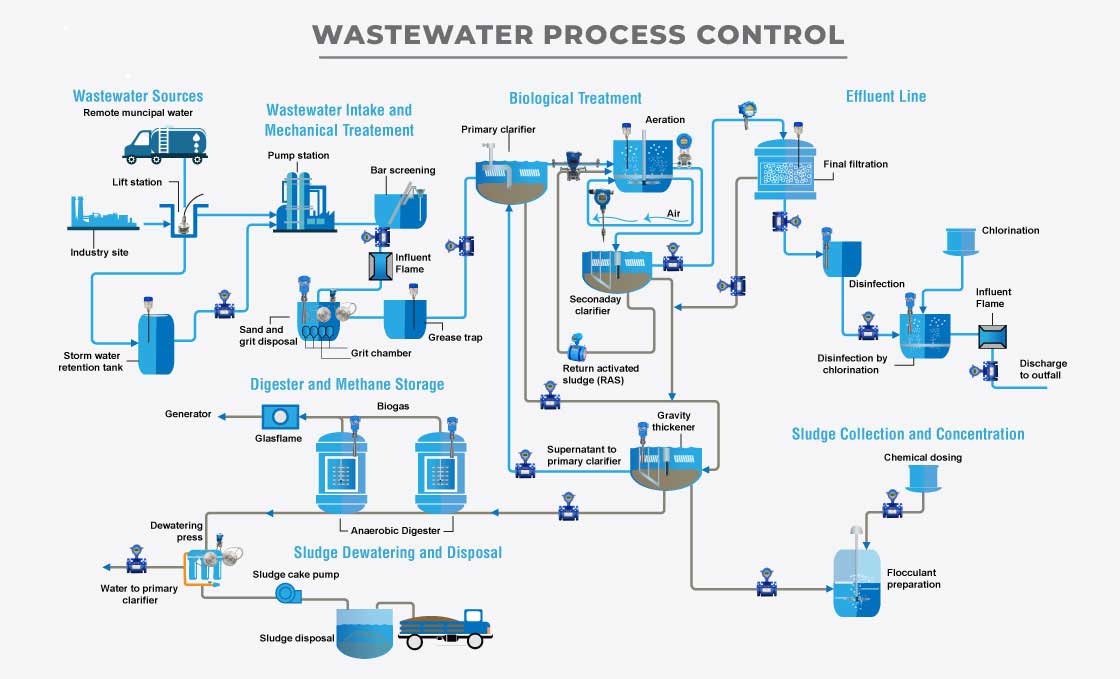

Wastewater

The monitoring of incoming wastewater should be sufficient to identify the characteristics which would affect the operation and

performance efficiency of the plant. Tek-Trol offers unique wastewater solutions tailored to these requirements for proper operation

of wastewater treatment plants. We offer cost effective and safe products as they are easy to operate and maintain while increasing

productivity. Our Flow, Level, Pressure instrumentation provide accurate and reliable measurement in Wastewater Treatment

process plant.

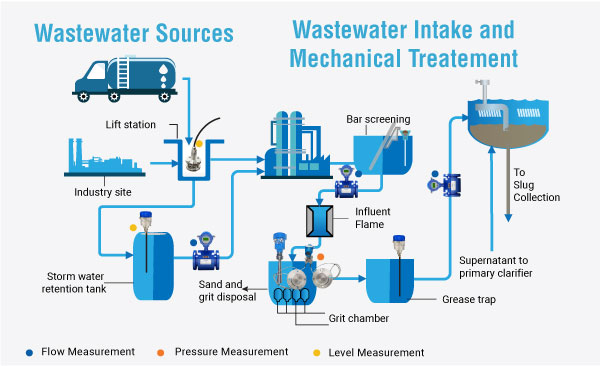

WASTEWATER SOURCES, INTAKE AND MECHANICAL TREATMENT

- Flow Measurement

- Pressure Measurement

- Level Measurement

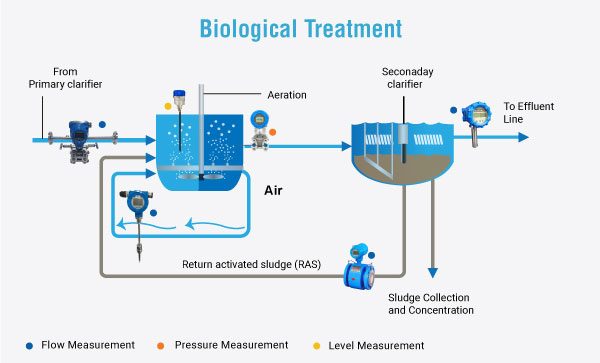

BIOLOGICAL TREATMENT

- Flow Measurement

- Pressure Measurement

- Level. Measurement

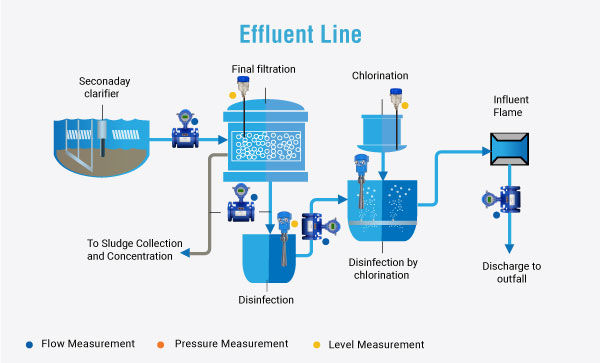

EFFLUENT LINE

- Flow Measurement

- Pressure Measurement

- Level Measurement

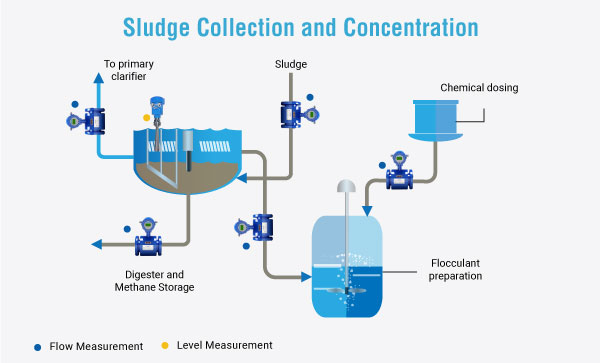

SLUDGE COLLECTION AND CONCENTRATION

Waste activated sludge (WAS) or untreated solids are further processed in the stabilization process. This sludge is collected from

the secondary settling tanks and pumped to the primary settling tanks. Tek-Trol’s Electromagnetic Flow Meter is used to measure

flow between secondary and primary settling tanks. This waste activated sludge is co-settled with primary sludge in the primary

settling tank. The co-settled sludge is automatically pumped to one of the two primary digesters for stabilization.

- Flow Measurement

- Level Measurement

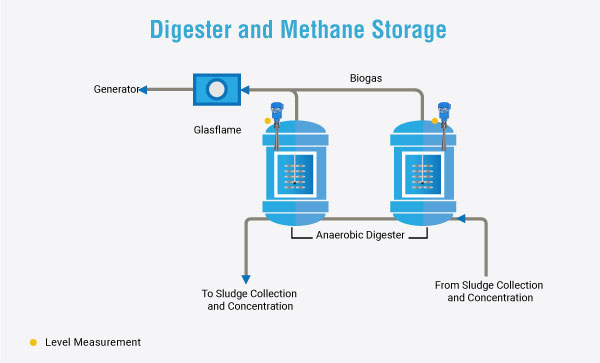

DIGESTER AND METHANE STORAGE

- Level Measurement

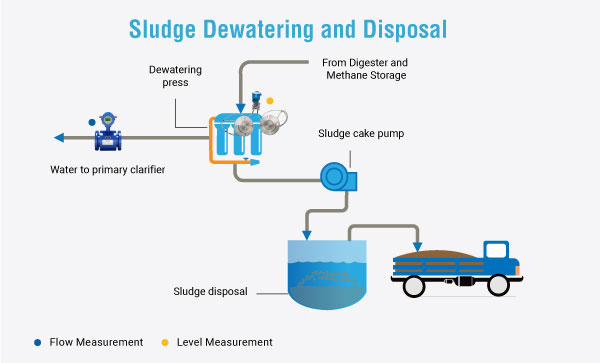

SLUDGE DEWATERING AND DISPOSAL

- Flow Measurement

- Level Measurement

RELATED PRODUCTS