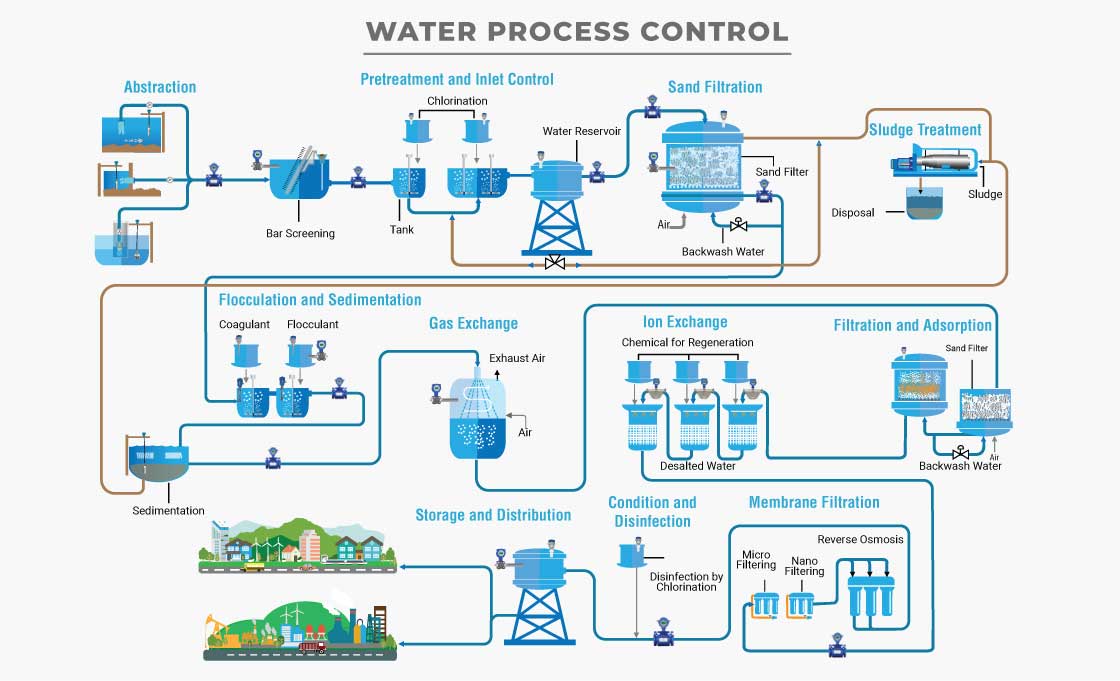

The provision of adequate water supply is essential for the development of entire regions. Tek-Trol provides highly advanced, market-oriented, and cost-effective measuring instruments and customized and fully equipped solutions. Our technology and products improve the performance of plants.

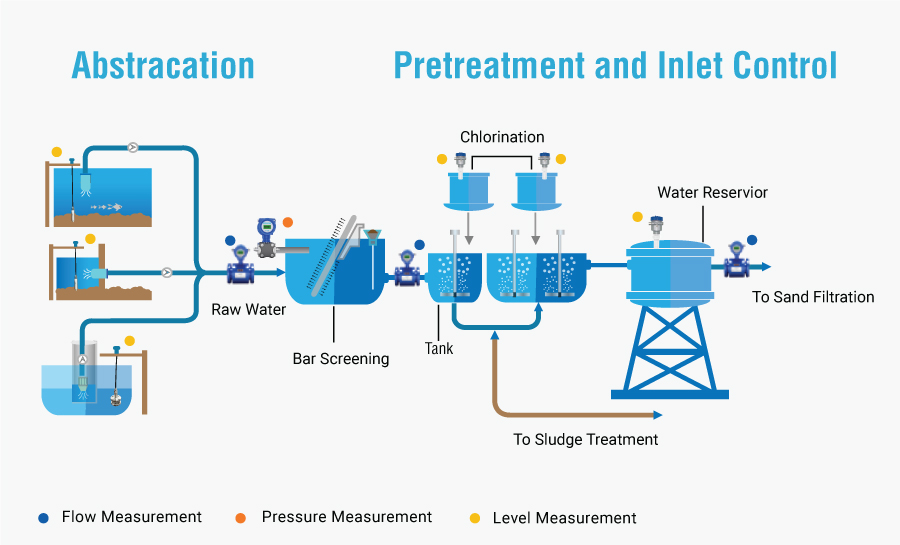

PRETREATMENT AND INLET CONTROL

- Flow Measurement

- Pressure Measurement

- Level Measurement

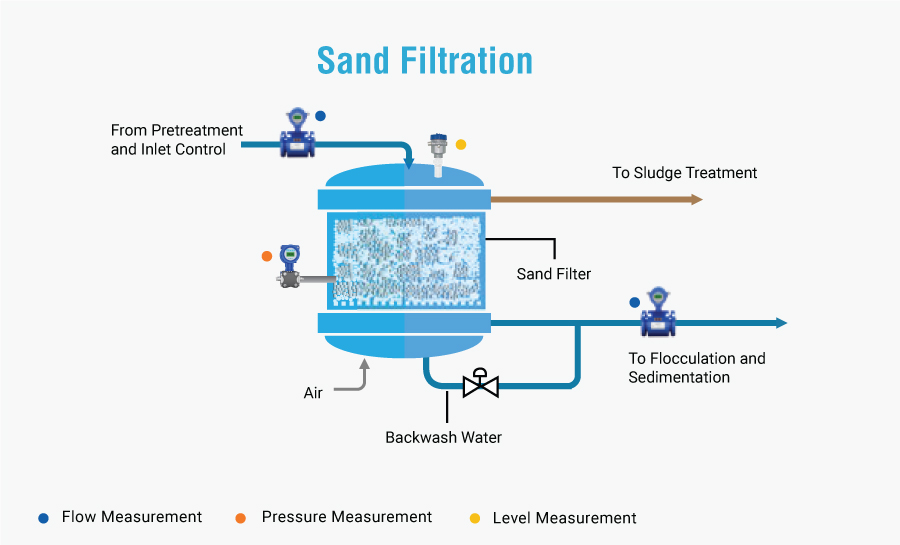

SAND FILTRATION

- Flow Measurement

- Pressure Measurement

- Level Measurement

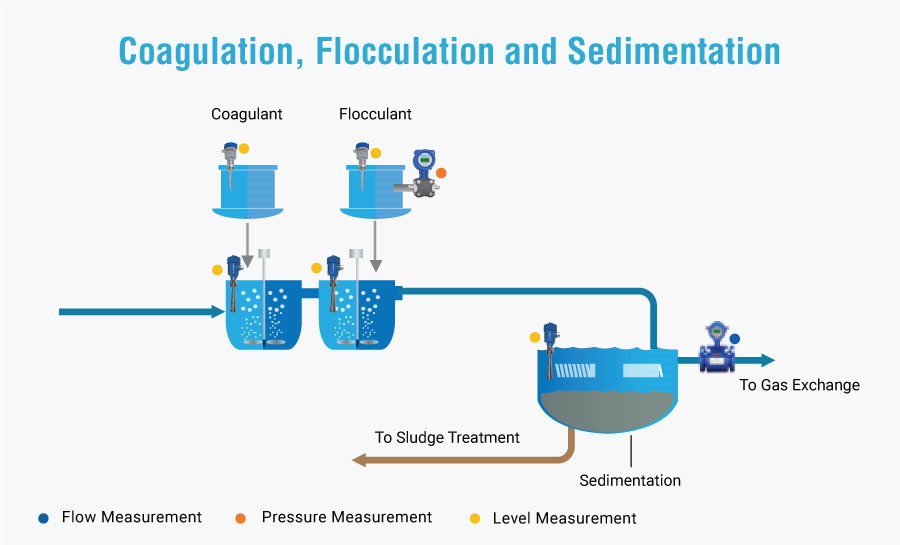

COAGULATION, FLOCCULATION AND SEDIMENTATION

- Flow Measurement

- Pressure Measurement

- Level Measurement

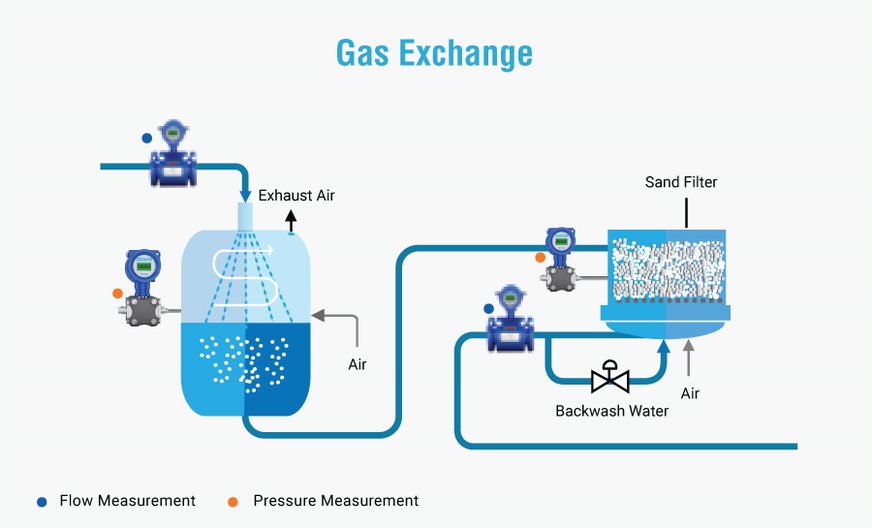

GAS EXCHANGE AND FILTRATION

- Flow Measurement

- Pressure Measurement

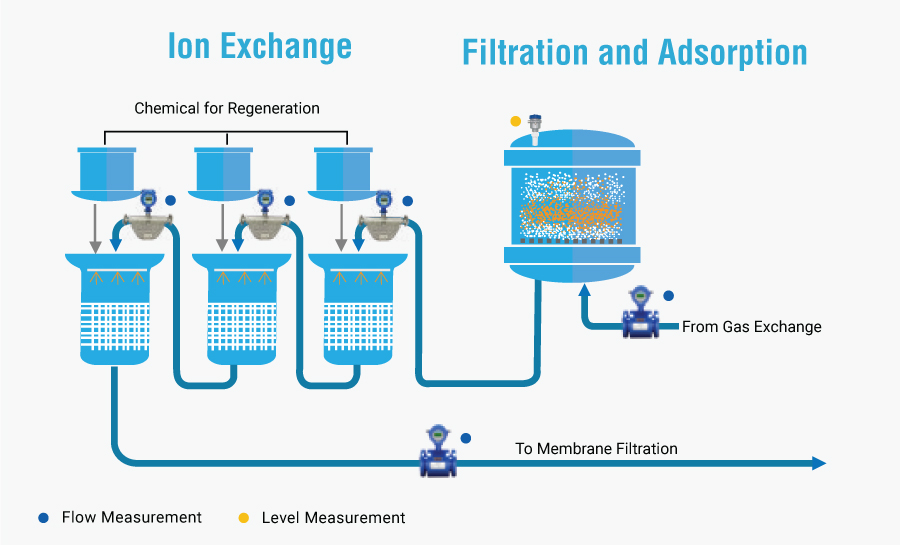

ION EXCHANGE PROCESS

- Flow Measurement

- Level Measurement

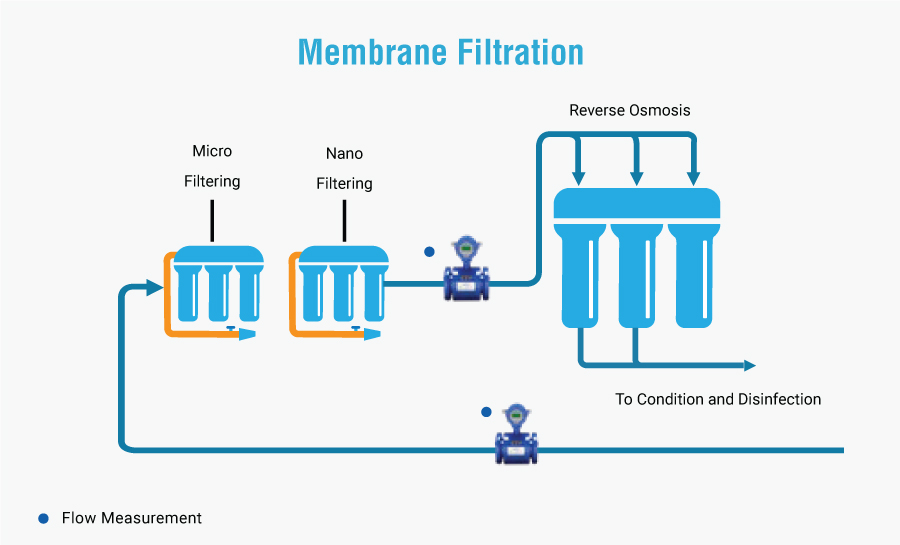

MEMBRANE FILTRATION

- Flow Measurement

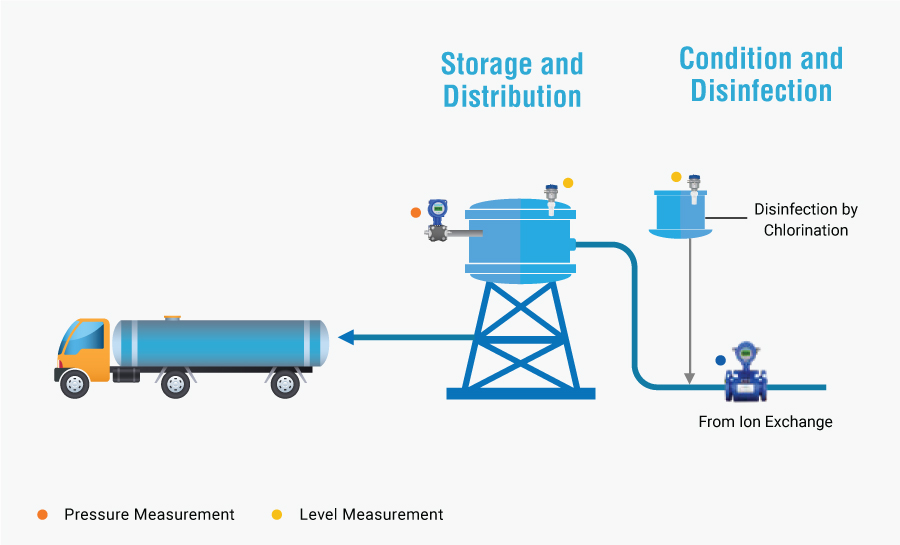

STORAGE AND DISTRIBUTION

The stored water is distributed through underground pipelines in homes, commercial areas, and the markets. Tek-Trol’s Differential pressure Flow Meter are used for DP flow measurement and Electromagnetic Flow Meter is used for full pipes flow measurement. The distribution system consists of large water pumps at the treatment plant, overhead water storage tanks, large pipelines, smaller pipelines, fire hydrants, valves, and water meters in your front yard. Tek-Trol’s Differential Pressure Transmitter is used for pump discharge and network pressure measurement.

- Flow Measurement

- Pressure Measurement

- Level Measurement

RELATED PRODUCTS